Swiss Smart Factory

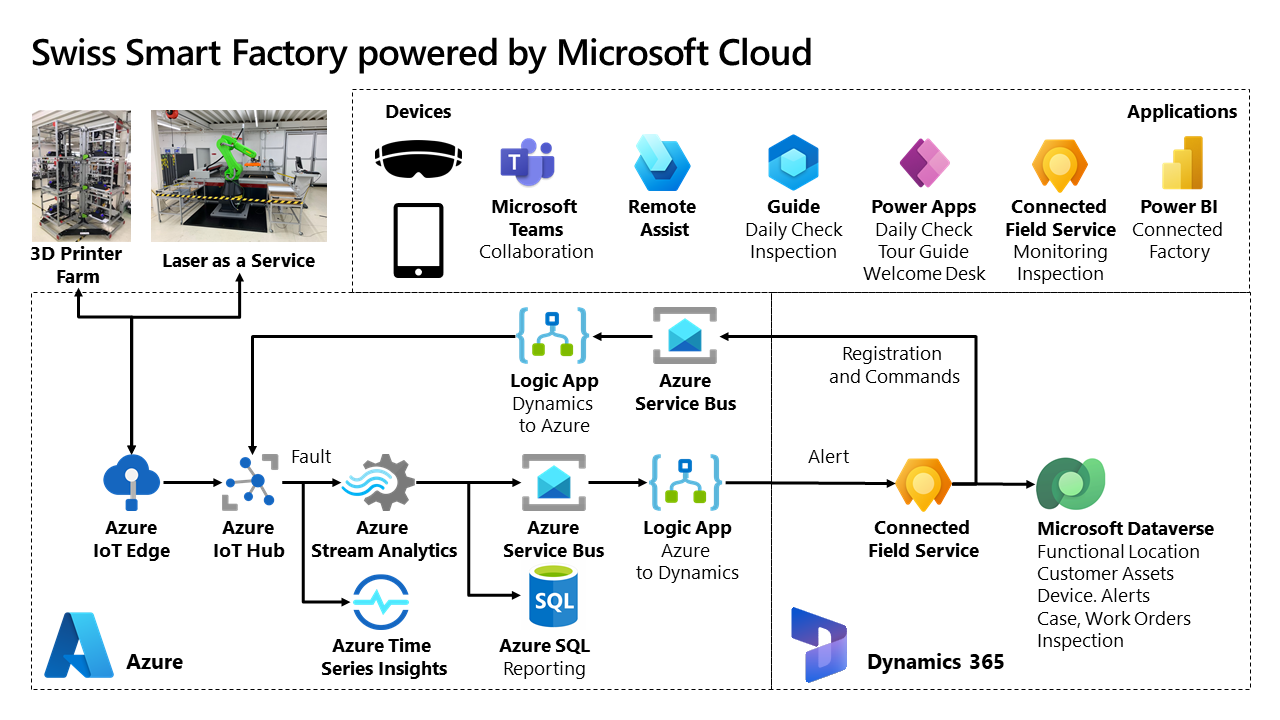

The Swiss Smart Factory (SSF) is the first test and demonstration platform for Industry 4.0 in Switzerland and with the lighthouse project «Drone Production», we intended to show how smart factories can already work today with an entire production ecosystem powered by Microsoft Cloud and our Partner ecosystem.

Take a virtual tour

To develop smart production and achieve higher added value, technologies are not only used on their own, but also together. Our focus here is not just on the machines, but rather the entire environment – building, infrastructure and machines. Thanks to this comprehensive data consistency of all work steps, information flows from developer to developer; from the developer to the machine; from the machine to the product; from the product to the customer and from customer back to the manufacturer.

The Lighthouse Project Industrie 4.0

Swiss Smart Factory

The Swiss Smart Factory is the place to learn and see all about the 4th industrial revolution. This video discusses where we use the Azure cloud and why the Swiss Smart Factory chose Azure Cloud to connect and engage different demonstrators in the Lighthouse Project Industrie 4.0.

Microsoft Cloud powered connected factory

«We build our lighthouse project on a scalable and secure Microsoft cloud platform to lay the foundation and run the production line to showcase it» Michael Wendling, Head Swiss Smart Factory Lighthouse project.

Microsoft Cloud powered connected factory

Connected Smart Factory enables organizations to transform the way they operate and service from a costly break-fix model to a proactive and predictive service model through the combination of IoT diagnostics, scheduling, asset maintenance, and inventory on the same platform.

Applications

Factory

3D Printer Farm: The 3D Printer Farm of the Lighthouse project Industry 4.0 is where drone parts are printed on 9 printer modules. The modules are connected over OPC-UA to inform about the process status and allows to retrofitted IO-Links sensors to gather additional information is needed.

Laser as a Service: The Laser as a Service is where printed drone parts get their finish.

Azure

Azure IoT Edge: Internet-connected sensors on 3D Printer Farm and Laser as a Service equipment send data to Azure IoT Hub via secured WLAN or LAN connectivity. A single equipment can have multiple sensors each taking different measurements such as progress status, temperature and pressure. The 3D Printer Farm is a collection of similar 3D Printer Module equipment each with multiple sensors and Azure IoT Edge device is used to organize them, and broker telemetry sent to Azure IoT Hub.

Azure IoT Hub: Is the gateway to the cloud, capable of ingesting data on a large scale from any IoT device. Azure IoT Hub is a collection of applications and processes tailored to connected device scenarios that are also customizable. Azure IoT Hub deploys a resource group with a collection of applications and processes.

Azure Service Bus: Takes faults and enters them into a queue to systematically keep track of them. The queue is helpful for scenarios where faults fail to get transferred to Dynamics 365 and should be attempted again after some time.

Azure Stream Analytics and Azure SQL: Used to store device data for longer time periods to perform data analysis. For example, the Power BI based Connected Factory application enables organizations interested in analyzing large amounts of historical data to predict device failures across their factories. Threshold rules helps to decide if device data is abnormal and beyond acceptable boundaries. Abnormal data is characterized as a Fault to be analyzed and managed by Factory Operator.

Azure Time Series Insights: Is designed for ad hoc data exploration and operational analysis allowing operators to uncover hidden trends, spotting anomalies, and conduct root-cause analysis.

Azure Logic App - Azure to Dynamics: Connects Azure with Dynamics 365. Serves as a way to apply more logic, map entities, and trigger the appropriate actions in Dynamics 365, such as the creation of an IoT Alert record.

Azure Logic - Dynamics to Azure: This adds detail to data and actions that need to be sent to Azure IoT Hub from Dynamics. Azure IoT Hub will then send the data or action to the connected device.

Dynamics 365

Microsoft Dataverse: Lets you securely store and manage data that's used by user applications: Power Apps, Connected Field Service, Guides, Remote Assist and Power BI Dashboards. In our case we manage Functional Locations, Customer Assets, Device, Alerts, Case, Work Orders and Service Activity.

Connected Field Service: A set of entities and processes built on Dynamics 365 Field Service. Connected Field Service allows you to connect IoT devices (sensors) with Field Service customer assets to be served remotely on on-site.

Alert: Faults are passed from Azure IoT Hub to Dynamics 365 in the form of IoT alerts, which is an entity in Field Service. An IoT alert is the first part of the process inside Dynamics 365. An IoT alert is a subset of all device data that requires attention and potentially an action from the service operator.

Registration and Commands: Processes used in Connected Field Service to interact with and send data back to Azure IoT Hub and finally to the device. Registration allows you to create a new device and register it in Azure IoT Hub. Commands allow you to execute actions on devices such as reboot.